Optical Inspection Systems

Optical Inspection Systems for the pharmaceutical packaging industry.

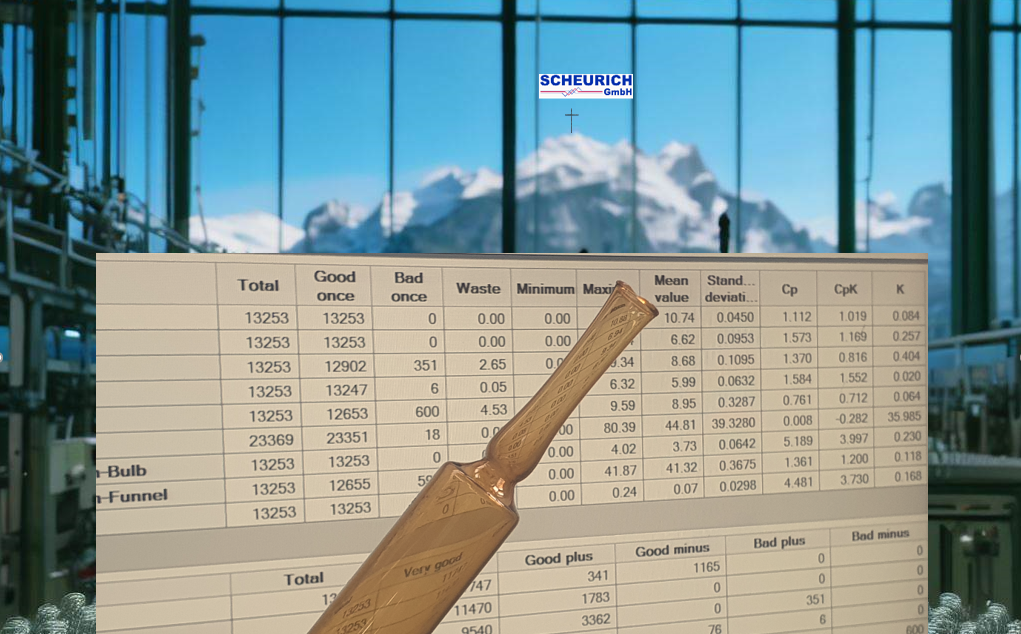

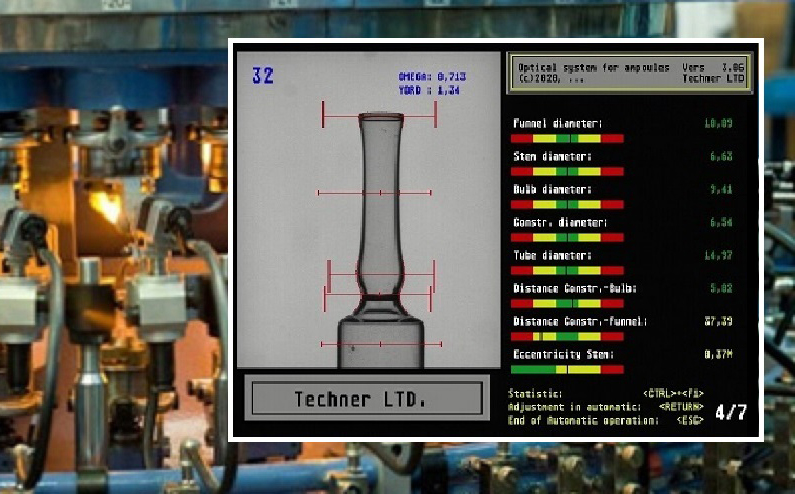

In terms of inspecting ampoules optically, we’re not just players – we’re leaders in the full-service and system provider arena within the pharmaceutical primary packaging industry. Our expertise shines through high-resolution cameras and lightning-fast signal processing. Alongside HotEnd and ColdEnd inspection, we supply OPC-Cutter systems and even have our own ampoule BreakForce device. Connecting of production lines with production statistics and productivity control through modern production dashboards make us one of the leading international system providers in this area.

Short version: There aren’t many providers with such a comprehensive and complete product range centered around ampoules.

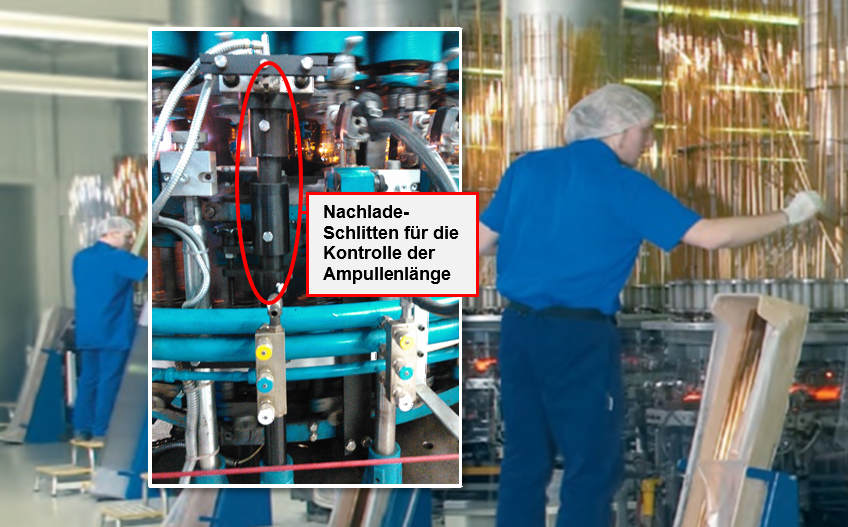

MRS22 HotEnd Inspection and Control System

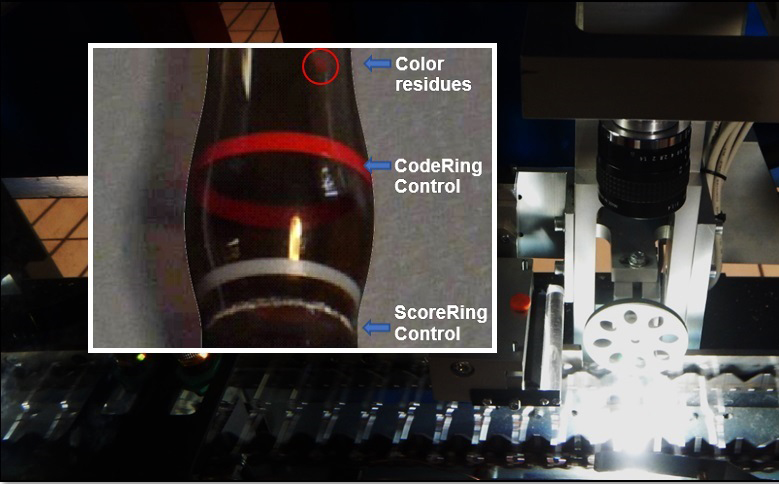

OPC + RingControl for ColdEnd Control (CEC)

PrintControl for ColdEnd Control (CEC)

FirstPiece Compensation (FPC)

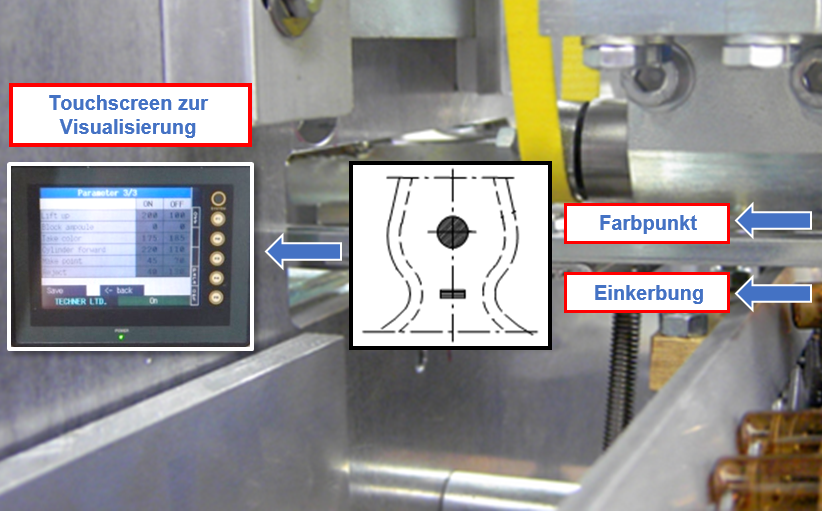

OPC Cutter System

BreakForce device BFT-150

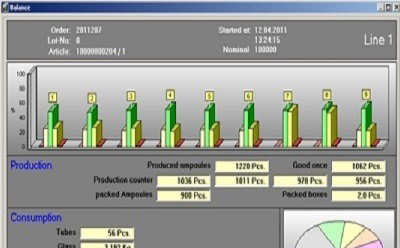

MES System MRS-Win

Interfaces to ERP

Contact Us – We’re Here to Advise You!

Leave us your email, and we’ll get in touch with you shortly for a non-binding conversation.

Our clients

And here you can see that we can work well with both small family-run companies and large international corporations: